Packaging is more than a container. It safeguards the contents, makes legal statements, affects end-user perception of your brand, and impacts transport, storage, and eco-impact. Low-cost, recyclable packaging could help food and drink manufacturers save costs, clear stocks, and boost sales, say packaging and recycling experts.

This guide takes you through food packaging, covering materials and barrier science, food contact regulations, UN/DOT, labeling, testing, sustainability, innovative packaging, and supplier selection. This way, you can make sound decisions without hopping through tabs.

Why Your Packaging Decisions Are Critical for Your Brand’s Success

Packaging is your brand’s silent spokesperson. The first impression a customer sees shows professionalism and care. A reliable pharmaceutical packaging supplier is crucial for patient safety in the pharmaceutical sector, as the packaging ensures the sterility of the medicine and provides information such as dosage and expiry. For food brands, packaging can signal to the customer whether a product is premium, sustainable, or convenient. Olive oil bottle packaging design can help a brand make a lasting impression and command a premium price. Local Illinois companies changed their sales simply by upgrading from stock containers to custom containers designed to bring out their brand’s personality.

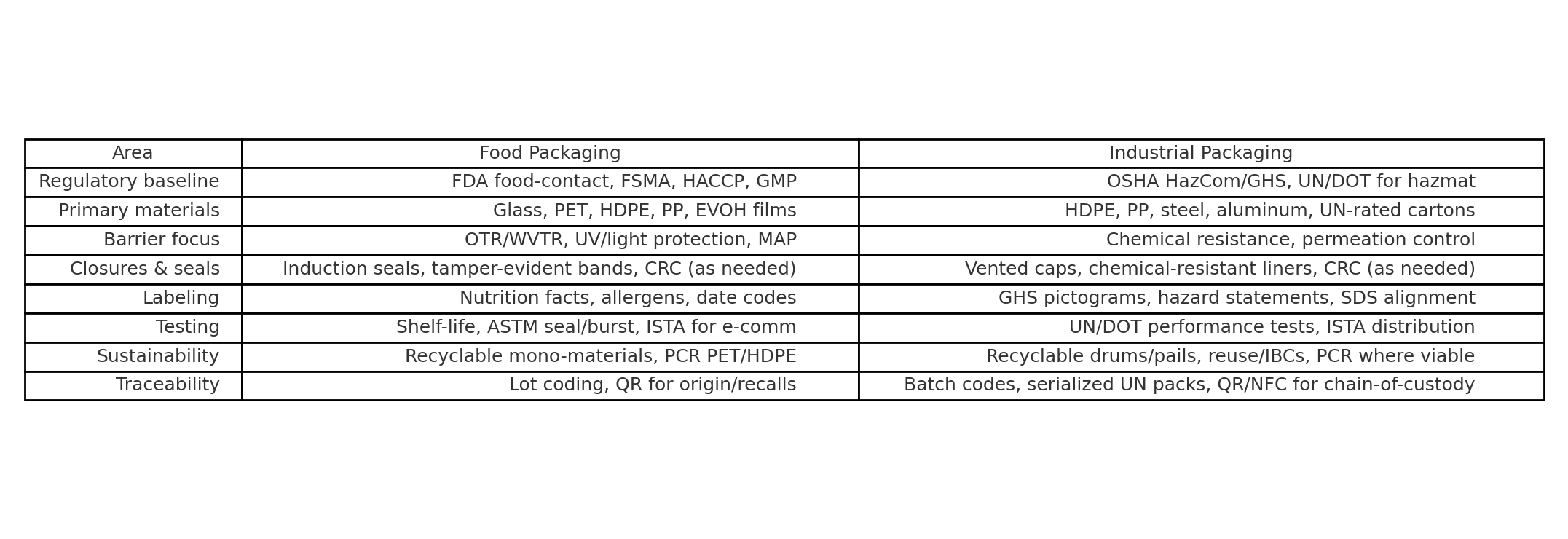

What Counts as Food and Industrial Packaging

Food packaging: safety first, brand always

Food packs must be food-grade and safe for people to eat. They also need to keep food fresh and look appealing on a shelf or online. A good bottle, pouch, tray, or jar delivers the shelf life you need by managing oxygen, moisture, and light. It must follow FDA food-contact rules, support FSMA/HACCP programs, and carry correct nutrition and allergen labeling.

Industrial packaging: durability and compliance

Industrial packing systems are manufactured to be strong, chemical-resistant, and EN 13432 compliant for pallet shipping. It guards against shocks, vibrations, heat, cold, and stacking loads. It must comply with GHS/OSHA HazCom labeling regulations and, in the case of a regulated liquid or powder, pass UN/DOT performance testing. Consider HDPE sprayer bottles, pails, drums, IBCs, and UN cartons that are robust enough to withstand real distribution, not just the factory floor.

Materials That Matter (and Why They Matter)

Plastics you’ll actually choose

-

HDPE (high-density polyethylene): Tough and chemical-resistant. Standard for milk jugs, detergents, and industrial sprayers. Good impact strength.

-

PET (polyethylene terephthalate): Clear and glossy with a strong gas barrier vs. HDPE. Great for packaging beverages, sauces, and olive oil bottles (with UV protection).

-

PP (polypropylene): It handles heat better and is common for cups, microwaveable trays, and snap lids.

-

Multilayer films: Laminates using EVOH (for oxygen barrier), nylon, PE, and sometimes metallized layers. These drive OTR/WVTR for pouches and lidding films.

Glass and metal

-

Glass: Inert (no flavor transfer), premium look, strong UV barrier when amber or green. Ideal for oils and gourmet sauces.

-

Aluminum: Cans and aerosols. Excellent light/oxygen barrier, endlessly recyclable.

-

Steel: Strong drums for coatings, solvents, and oils.

Paper and fiber

-

Corrugated: Shipping boxes that protect units and pallets. Board grade and flute choice affect compression strength.

-

Paperboard: Folding cartons and sleeves that carry print and brand cues.

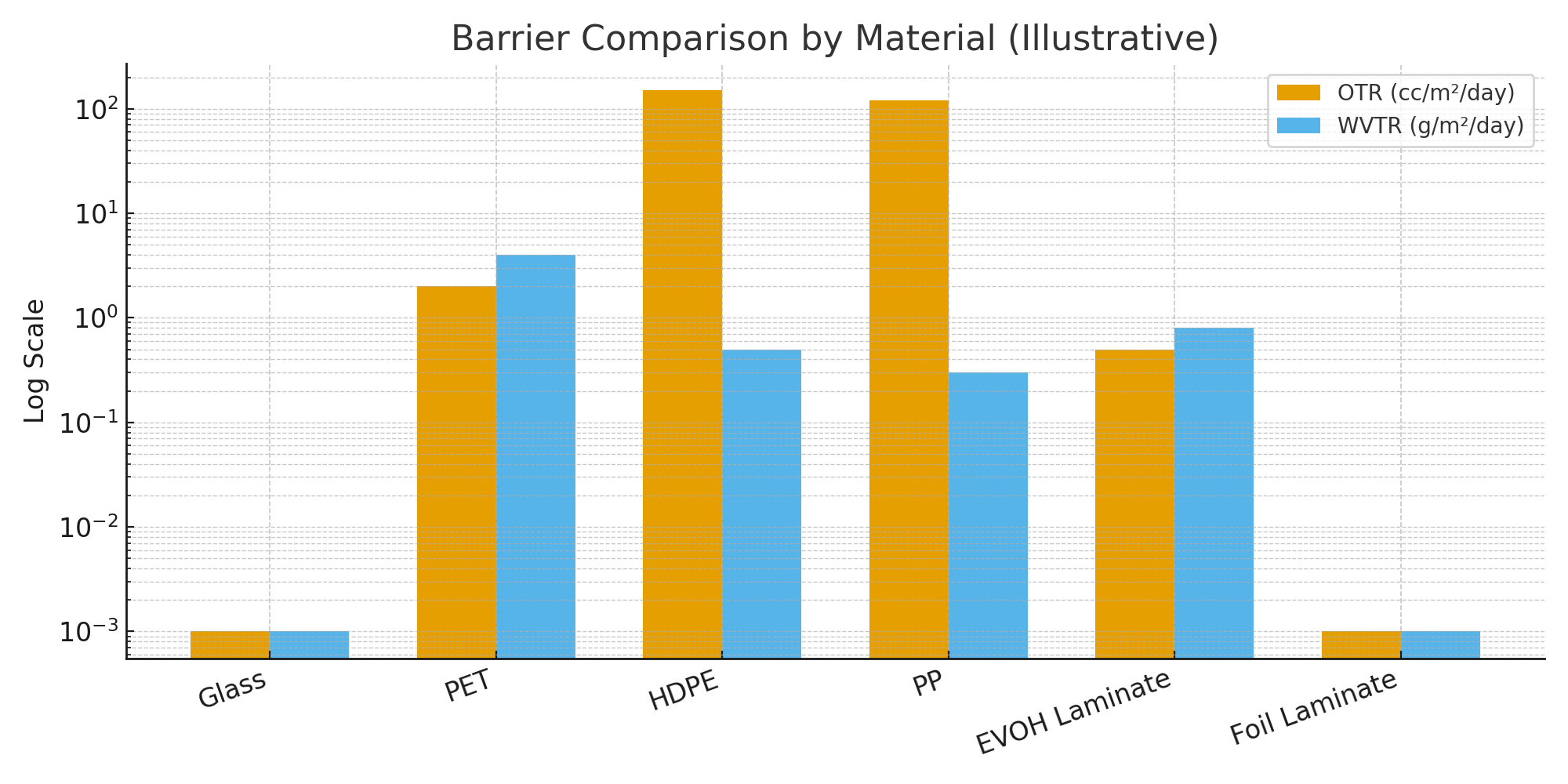

Barrier basics (plain English): Oxygen spoils oils and colors. Moisture makes snacks stale. Light speeds rancidity. Pick materials with the right barrier properties so your product tastes and looks right for its whole shelf life.

Compliance and Food Safety By Design

Food compliance framework (keep it simple and safe)

-

FDA food-contact: Use approved resins, inks, and coatings with safe migration levels (21 CFR). Ask for food-contact letters from suppliers.

-

FSMA/HACCP/GMP: Treat packaging as an ingredient. Audit vendors, track lots, and write changeover procedures for allergens and inks.

-

Labeling: Nutrition facts, allergens, ingredient order, net contents, date coding, and country of origin, if needed.

-

Tamper-evident and child-resistant where risk applies (supplements, alcohol, edibles, concentrated cleaners).

Industrial compliance framework (tell it like it is)

-

UN/DOT performance packaging for hazmat: Inner bottles + outer cartons tested as a combination. Ensure the correct packing group (I/II/III) and codes are on the box.

-

GHS/OSHA HazCom: Labels must match the SDS, show pictograms, hazard statements, and signal words.

-

State rules: Watch EPR (extended producer responsibility) fees, VOC limits, and container deposit/refill laws in your markets.

Barrier Science and Shelf-Life Engineering (No Jargon, Just What Works)

Pick a shelf life, then engineer backwards.

-

Set a realistic shelf-life goal at your worst expected temperature and humidity.

-

Choose materials that hit your OTR and WVTR targets. EVOH for oxygen. Metallized or foil for light.

-

Add extras if needed: oxygen scavengers, desiccants, or MAP gases (CO₂/N₂) for fresh foods.

-

Validate with ASTM tests and sensory checks to make sure you don’t get off-flavors or aroma loss (called scalping).

Format changes performance

-

Bottles/Jars: Headspace and closure liners (F-217, foil induction, pulp/poly) control oxygen ingress and leaks.

-

Pouches: Great barrier per gram of material; zippers and laser scoring help open/close without damage.

-

Trays/Lids: MAP trays keep protein and produce looking fresh; peel strength must balance seal integrity with easy open.

Closures, Ergonomics, and Leak-Proof Confidence

-

Induction seals stop leaks and extend freshness. They also signal tamper evidence.

-

Match the liner chemistry to the product. Solvents may need foil/heat-resistant liners. Oils often pair well with F-217 foam.

-

Use torque testing so caps are tight enough for shipping but not impossible to open.

-

For industrial sprayers, specify the trigger output, dip-tube length, venting, and elastomers (Viton, EPDM) that won’t swell or crack.

Design That Sells and Informs

Graphics and decoration

-

Pressure-sensitive labels, shrink sleeves, or direct screen printing each change recyclability, look, and cost.

-

Keep type readable, colors consistent (PMS), and claims honest.

-

Add QR codes or NFC for traceability, authenticity checks, recipes, or how-to videos (GS1 Digital Link format is a plus).

Structure and usability

-

Right-size your packs to reduce freight cost and waste.

-

Add ergonomic grips, pour spouts, and handles that prevent mess.

-

Think accessibility: larger type, easy-open lids, and tactile features help more people use your product confidently.

Sustainability Without Greenwashing

-

Design for recyclability: use mono-material where possible and avoid heavy inks/adhesives that gum up recycling.

-

Use PCR (post-consumer recycled) PET/HDPE when performance allows, test for color, odor, and strength.

-

Add refill/reuse options: concentrates with refill pouches, or closed-loop returns in B2B.

-

Use LCA (life-cycle assessment) to compare PET vs. glass vs. cans on real impact (energy, transport weight, end-of-life).

-

Follow the FTC Green Guides to keep environmental claims truthful and transparent.

Cold Chain and Thermal Packaging (Food and Pharma Adjacent)

-

Insulated shippers (EPS or paper-fiber alternatives) paired with gel packs or phase-change materials keep temperatures steady.

-

Validate routes for summer peaks; include printed time-temperature indicators or connected loggers if required.

-

Use tight pack-outs to limit void space and thermal swings.

Testing: Where Good Ideas Become Good Packs

-

ISTA 3A/6 distribution testing simulates drops, vibration, compression, and climate changes.

-

ASTM tests for seal strength, burst, torque, and leakage prove the effectiveness of your closure and film windows.

-

Run line trials on your actual filler/co-packer to confirm speed, reject rates, and downtime before buying large volumes.

A short, sharp test plan saves months of rework.

Cost Modeling: Beyond Unit Price

-

Think Total Cost of Ownership (TCO), not just unit price:

-

Unit + freight cube + pallet efficiency + damage/returns + line labor + obsolescence + compliance risk.

-

-

MOQ and lead times: balance custom tooling against cash tied up in inventory. Consider VMI (vendor-managed inventory) for fast movers.

-

Freight math matters: lighter, cube-efficient packs reduce parcel/LTL costs and improve margin more than a tiny unit-price win.

Finding a Full-Service Partner: More Than Just a Supplier

Due to the complexity of packaging for these industries, it is not just about buying containers. You need a partner who can provide end-to-end solutions. It isn’t only sourcing and distribution but also decorating, labeling, warehousing, etc. A good pharmaceutical packaging supplier must provide serialization and traceability to meet strict compliance demands. A full-service partner supports your operations and shares business insight. This reduces the workload for your team, giving you more time and energy to focus on what matters – product and marketing. How can you be sure that your supplier has everything your supply chain needs?

Choosing the Right Packaging Partner

What “full service” should actually include

-

Design & engineering: CAD, 3D prints, drop/fill simulations, barrier modeling, prepress.

-

Regulatory: FDA food-contact paperwork, GMP, FSMA support, UN/DOT testing, and GHS label checks.

-

Decoration: PSL, sleeves, screen, hot foil; color management and proofs.

-

Supply chain: multi-plant sourcing, local warehousing, EDI, and VMI.

10-minute supplier checklist

-

Written GMP/ISO quality system and recall drill records

-

Food-grade or chemical-grade cleanroom, where needed

-

In-house or partner ISTA/ASTM lab certifications

-

Financial stability and dual-sourcing options for critical items

-

Documented SLA for quality, lead times, and corrective actions

-

Food-contact letters and migration data for all intended uses

-

UN/DOT codes and recent test reports for hazardous shippers

-

Proof of color control (Delta-E reports) for brand fidelity

-

Sustainability roadmap (PCR options, recyclability design)

-

References from brands in your category

Packaging for Specific Verticals (At-a-Glance)

Olive oil and premium sauces

-

Dark glass or high-barrier PET for UV protection, along with a low OTR closure and an induction seal.

-

Drip-controlled spouts and tamper evidence.

-

QR or NFC for origin, harvest notes, and authenticity.

Snacks, bakery, and coffee

-

High-barrier pouches with tuned WVTR/OTR; one-way degassing valves for coffee.

-

Resealable zippers; MAP for fresh bakery.

Industrial cleaners, coatings, and lubes

-

HDPE bottles with chemical-resistant liners; vented closures to handle off-gassing.

-

Trigger/foamer compatibility testing with your chemistry.

-

UN/DOT certified shippers; GHS labels matched to the SDS.

Personal care and OTC

-

CRC where needed; clear tamper evidence.

-

Sensory testing to prevent fragrance scalping; migration checks for inks/coatings.

-

E-commerce ready (ISTA 6-Amazon).

Smart & Connected Packaging (Optional but Powerful)

-

QR/NFC/RFID enable traceability, anti-counterfeit, refill enrollment, and dynamic content.

-

Serialized lots that tie into GS1 standards and your ERP make recalls and audits faster and cleaner.

-

For the cold chain, data loggers and Bluetooth probes give instant proof of compliance.

Implementation Roadmap (Idea to Shelf Without Drama)

-

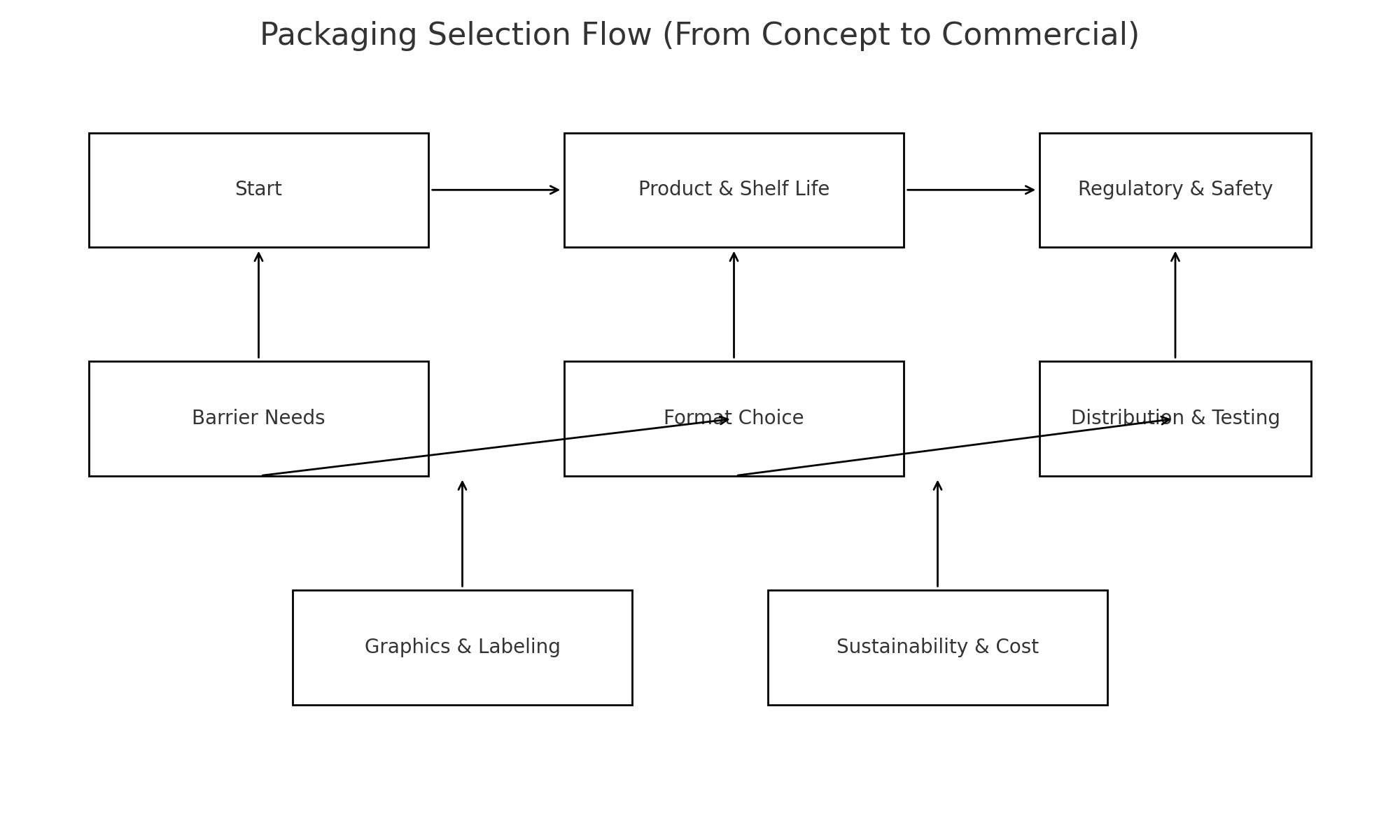

Define success: Shelf life, channels (retail, e-comm, B2B), drop/vibration limits, sustainability goals, and budget.

-

Map risks: Oxygen, moisture, light, temperature, chemistry, and misuse.

-

Select materials and format: Bottle vs. pouch vs. tray; closure and liner selection.

-

Prototype and lab test: OTR/WVTR, seal strength, torque, drop/leak tests; sensory checks.

-

Regulatory review: Food-contact letters, FSMA/HACCP docs, UN/DOT certification, GHS label proof.

-

Line trials: Real filler speeds, rejects, cleanup time, and changeover windows.

-

Finalize artwork: Legal review of claims, Green Guides compliance, nutrition facts, and warnings.

-

Scale and monitor: Supplier scorecards, returns analysis, damage/freshness KPIs, on-time/quality metrics.

-

Improve continuously: Light-weighting, PCR trials, mono-material shifts, SKU rationalization, better pallet patterns.

FAQs (Short, Straight, Useful)

What does “food-grade” actually mean? It means the material is safe for direct food contact per FDA rules. Ask for food-contact letters and migration data from your supplier.

What are OTR and WVTR? OTR measures how much oxygen passes through a material. WVTR measures water vapor. Lower numbers usually mean better protection and longer shelf life.

Are pouches more sustainable than bottles? Sometimes. Pouches often weigh less and ship efficiently, but recycling can be harder. Use LCA to compare your product and region.

How do I stop leaks? Use induction seals, match liners to product chemistry, set proper cap torque, and validate with ISTA drop and compression tests.

When do I need UN/DOT packaging? When shipping regulated hazardous materials. Your SDS and carrier rules will tell you. You’ll need tested combination packs with the correct codes on the box.

Can I use recycled plastic in food packaging? Yes, PCR PET/HDPE from approved streams is widely used. Test for strength, color, and odor, and confirm FDA food-contact status.

Mini-Glossary

-

Food-grade packaging: Safe to touch food per FDA rules.

-

OTR/WVTR: How much oxygen or moisture a package lets through.

-

MAP: Filling packs with protective gas to slow spoilage.

-

Induction seal: A foil seal bonded to the rim using electromagnetic energy.

-

CRC: Child-resistant closure (push-and-turn style).

-

EPR: Laws that put end-of-life costs on producers.

-

ISTA/ASTM: Test standards for shipping abuse and seal/strength checks.

-

GHS/OSHA HazCom: Hazard symbols and wording for chemicals.

-

UN/DOT: Performance rules for shipping hazardous materials.

Final Takeaway

High-quality packaging provides safety, compliance, information, enjoyment, and return on investment. When it comes to food applications, ensure that they are made from food-grade materials that demonstrate proven barrier properties. Also, ensure that the labels used are helpful for users, while the design provides brand-building benefits.

In industrial applications, this translates to rugged materials, UN/DOT and GHS compliance, and leak-proof ergonomic dispensing. One advantage of testing and honest sustainability is that they’re a full-service partner capable of designing, certifying, printing, stocking, and delivering on time and on spec. When packaging is treated as a strategic asset, it can reduce damage, increase line speed, improve margins, and delight customers.