You’ve heard the same complaint over and over: The problem is we need more people! Ok no. The problem isn’t that you need more people.

The problem may be that all of the mail isn’t getting delivered by 5:00 pm. That may be a problem.

One of the reasons, or causes, or the delay in delivery is that you may be in the midst of a hiring freeze and therefore you don’t have as many mail carriers as you used to.

However, the problem is not that you need more people. The problem is also not that you need more money or that you need more time. Those are not problems.

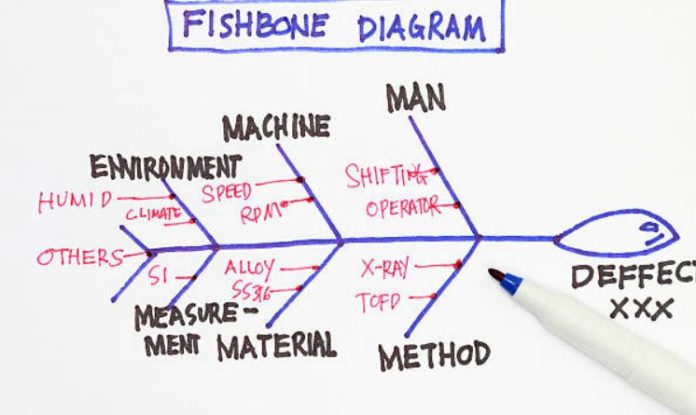

One way to find the problem to any given situation, so that you are better equipped to find a viable solution to the problem, is to construct a fishbone diagram.

Other names for the same graphical depiction are called Ishikawa Diagram, Root Cause Analysis or Cause, and Effect Diagram. This tool was named after the inventor, Kaoru Ishikawa who first used the technique in the 1960s.

The purpose of using a fishbone is to arrive at a handful of main causes that contribute most significantly to the problem being examined.

These causes are then targeted for improvement. The diagram also shows the relationships between the wide ranges of possible contributors to the effect.

When you’re done constructing your diagram, it will look like a fish carcass, thus the name fishbone diagram.

The problem that you’re targeting will be in a box, or the head of the fish to the far right of your paper.

Then you’ll draw a horizontal line across the page. Off of the horizontal line, you’ll draw four vertical diagonal lines (bones) which will each represent a different main grouping or cause category. Two will protrude on top of your horizontal line and two will fall below the line.

Label each of the bones with the following titles: Manpower, Materials, Machines, and Methods. These will serve as springboards for you to further delve into each cause.

For example, under Manpower this is where your staffing issues are listed. Perhaps you’ll add a small horizontal bone coming off this one that says hiring freeze and another bone labeled training.

Continue on with the next bone. Under Machines you could have bar code sorter rejects then not enough techs.

Pretend you are a three-year-old and keep asking WHY? The rule of thumb is to ask Why? five times for each category. Carriers don’t return to the office until 6 pm.

Why? (#1) Because we don’t have enough to cover the routes. Why? (#2) Because some have retired and we can’t hire more.

Why? (#3) There’s a hiring freeze. Note: Going further on the hiring freeze may not help if that decision is beyond your span of control.

Therefore, switch gears if you truly have no authority to change a situation. Sometimes carriers aren’t getting back until dark because they have to pivot and help other routes, Why? (#4) Because the new carriers are slow.

Why (#5) because they’re not getting out of the office until 1300, so there’s no way they can get back by 1700. Ok, stop. Now you have a definitive situation to review, brainstorm, and find a solution.

Now your problem may have just become: New carriers aren’t leaving for the street until 1300. Then you can repeat the above process and dig deeper until you can find the TRUE root cause.

Then fix your problem. Many times managers fix problems that aren’t broken. Only to find their original problem still exists.

Keep these tips in mind when creating your Ishikawa:

1. Place the main problem you’re trying to solve in a box on the right, for the fish’s head.

2. This tool works alone or in team settings. Generate and clarify all the potential sources of variation.

3. Sort your possible causes into naturally related groups. (Use manpower, machines, materials, and methods as your guide when grouping them). The labels of these groups are the names for the major bones on the Ishikawa diagram.

4. Place all the causes that you’ve just brainstormed on the appropriate bones of the diagram.

5. Ensure that the causes are specific, measurable, and controllable. Meaning if you can’t measure progress or defects or if you don’t have a span of control to do something about it, select another cause that you can actively work to rectify.

As you find solutions to little problems, continually rework your diagram. You’ll be amazed at the small incremental steps you’ll make at improving your overall operations.

This visual depiction of the problems will help you stay focused on true root causes and solutions. No longer will you operate off complaints such as The problem is we don’t have enough people!